Advantages of using metallurgical equipment orders site for whole enterprise business management in network

How can these metallurgical equipment orders site solutions help manage a company's day-to-day business activities such as accounting, finance, procurement, project management, supply chain and manufacturing? metallurgical equipment orders site refers to a fully integrated platform deployed on-premises or in the cloud, primarily for managing all aspects of a manufacturing or distribution business. In addition, metallurgical equipment orders site also supports the comprehensive financial management, human resource management, supply chain management and manufacturing management of the core accounting functions of the enterprise. Metallurgical equipment orders site tracks all aspects of production, logistics and financial processes, providing transparency across the entire business process. These integrated systems serve as the central hub for end-to-end workflow and data across the enterprise, making it accessible to various departments. Metallurgical equipment orders site is designed to support multiple functions of small and medium-sized enterprises, including providing customized functions for your business.

For most metallurgical equipment enterprises, metallurgical equipment orders site focuses on the unified management of logistics, capital flow and information flow in the process of purchase, sales and production. Usually, category, application, specification, model, configuration, etc. Enterprises, as a node in the industrial chain, only pay attention to the material and capital transactions of upstream and downstream suppliers and customers directly related to themselves, as well as their own production, processing and assembly flow.

LongRiverTech metallurgical equipment orders site provides a full set of project consulting, product customization development, project deployment and implementation, and online cloud platform customization and operation of technical services to meet the industry needs of category, application, specification, model, configuration, etc..

LongRiverTech engineering management includes: project, material, contract order, accounting integration, and can meet the special industry needs of the category, application, specification, model, configuration, etc..

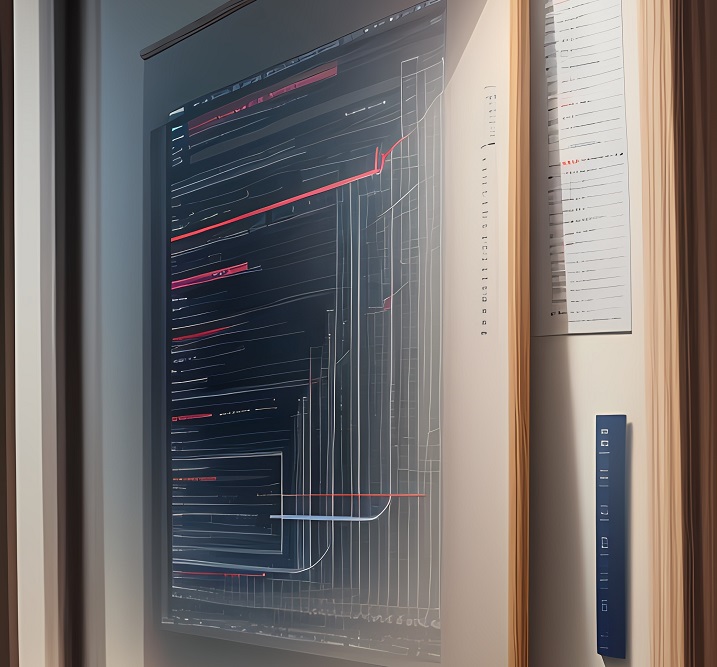

Compared with other software, the business intelligence analysis in the product has the biggest feature: the system does not limit the content and conditions of query analysis, which can be flexibly defined by users. At the same time, the software summarizes and refines the analysis models of existing customers, and compiles a large number of analysis templates for customers to use. Business intelligence includes three parts: business process analysis, comprehensive analysis and wizard report. Among them, business process analysis provides information covering "production", "purchase", "order", "distribution", "direct sales", "retail", "price", "warehousing and logistics", "finance", "customer relationship", The process of each business link such as "items". Metallurgical equipment orders site security and background management Through multiple operation and maintenance monitoring and security guarantee mechanisms to ensure enterprise information security, enterprises can set up administrator background management. Group goods delivery plan: used to formulate regional delivery plans for commodities. The resource management functions required for sales include: quotation, signing, delivery, and payment collection. The resource management functions required for procurement include: demand, documentary, receipt, and payment. The resource management functions required by the warehouse include: how much to receive, how much to send, and how much to store. The resource management functions required by production include: what is demanded, what is produced, and what is purchased. The resource management functions required by the project include: price control, bill of materials, and approval process. More inventory warning, more reasonable control. The inventory software sets the upper limit and lower limit alarm line. When the current inventory of goods exceeds the upper limit and lower limit, an automatic alarm will be sent to the warehouse manager to remind the manager to take corresponding measures. Closed-loop product design, from the beginning of product planning, to task assignment, design process control, pattern making, pattern review, and finally into the closed-loop production management of order meeting tracking results. Customized clothing industry, designed and produced according to customer requirements. Generally speaking, customers are used to customizing clothing in the second half of the year. This has caused the clothing company's annual output to be very unbalanced. It is necessary to better regulate production, balance output value, control delivery deadlines, and straighten out internal processes. The internal production mode of the enterprise needs to be changed. The traditional manual input and manual data transmission cannot obtain timely and accurate reports required for leadership decision-making. In the later stage of production, for example, the data information required in links such as logistics, delivery, and quality inspection are all allocated and expanded by the system. All information must be accurate from the source of data entry, so that the follow-up work can ensure that the error rate is reduced, thereby reducing costs.

LongRiverTech metallurgical equipment orders site limit risk control supports advance receipt inquiry and write-off, advance payment inquiry and write-off, receivable inquiry and write-off, payable inquiry and write-off, credit limit inquiry and details, risk exposure inquiry and details . LongRiverTech metallurgical equipment orders site defaults to single currency, which simplifies system operation. LongRiverTech metallurgical equipment orders site supports multi-currency and foreign exchange business, including: foreign exchange exchange, import and export customs, tax calculation, etc. LongRiverTech metallurgical equipment orders site retail return order includes: create retail return order, view retail return order flow, reverse retail return order, view retail return order documents, print retail return order documents, and export retail return order documents.

Security engineering management systems include: project monitoring management software system, monitoring security project management software system, intelligent building quality monitoring and control security system, construction project security company management system design, technology research and development project management information system, research and development intelligent project control management system, Research and develop the PM construction project management information system, the owner's project quality control management system. If the customer requires one-time delivery, but due to the negligence of the company's shipping administrator, the order is only partially completed, and the goods are hurriedly delivered to the customer company. Thus, resulting in customer complaints. The administrative management functions of the resource management system include: equipment management, attendance management, office supplies, document management, document management, conference management, vehicle management, basic settings, and initial settings. It is conceivable that the establishment of the product database (BOM) restricts the implementation of resource management. Everyone says that the implementation of resource management is difficult. We understand that the most difficult thing is the improvement of the product database. Many companies implement resource management slowly or abnormally. It is often stuck on the imperfection of the database. However, as long as the enterprise has a strong implementation team and the implementers have the spirit of perseverance, and overcome the management and data barriers, the road to successful implementation of resource management will be revealed. Resource management system financial management: initial setting, fixed asset management, cashier management, financial processing, report management, basic settings, financial budget management, budget control, progress control, project files. When customizing the financial management module, generally consider: credit management, innovation impact analysis, bidding financial management, financial indicators, financial management method configuration, financial decision support, financial management tool collection, financial management theory implementation, financial evaluation indicators, Financial strategy management, financial management audit support, financial management model configuration, financial analysis reports, etc. Metallurgical equipment orders site cloud platform is suitable for fast-growing enterprises to realize the control and coordination of production, supply, sales, personnel, talents, and materials; improve the operating efficiency of enterprises and speed up the response speed. Because traditional financial data is recorded manually, and this kind of data is prone to errors during the recording process, and it is also very difficult to find when it is found. When some small and medium-sized enterprises record financial data, they still use journals to keep accounts, which is more likely to cause accounting errors and cause poor registration of financial data. After using metallurgical equipment orders site, it is easy to The financial data can be recorded through the financial management function, so that the financial data can better provide decision-making basis for operators.

Small and medium-sized metallurgical equipment enterprises focus on production and processing to drive upstream procurement and downstream order management. The conventional metallurgical equipment orders site satisfies the large-scale production management of batch products. Mass-produced products with a high degree of standardization can quickly reach saturation through large-scale expansion, leaving a lot of room for growth in non-standard orders that require individual customization. For more innovative non-standard orders, it is increasingly dependent on the auxiliary management of computer systems to cope with the explosive growth of business data. Metallurgical equipment orders site can view commodity sales (retail) ranking, customer sales ranking, sales (retail) details, sales (retail) monthly report, sales (retail) weekly report, sales (retail) daily report, employee profit, customer profit. LongRiverTech metallurgical equipment orders site enables object support. LongRiverTech metallurgical equipment orders site manages the batches of goods in the warehouse by default, and can further track and manage individual objects for scanning code entry, exit, inventory, and transportation. Metallurgical equipment orders site project management functions include: project, task, label, article, idea, document, user, manpower, customer, rate, log, progress, plan, quality, risk, status, scheduling, WBS, priority, Pricing, associations, sales, collections, hours, billed costs, allocations, values, invoicing, and production imputation. LongRiverTech metallurgical equipment orders site processing cost sheet supports the management of processing flow, raw materials and output materials, expenses and profits, and bookkeeping costs.

Print the logistics list and distribute the express delivery. The system can automatically assign a courier company to each order according to the following principles. According to the distribution area of the logistics company; according to the express delivery with the lowest logistics cost. According to the company's designation and customer's request, the order is printed separately. When the order volume is very large, the enterprise usually uses multiple printers to print the order at the same time. A certain printer can be defined to exclusively print a certain logistics company's face sheet, and the system can automatically find the printer to print according to the logistics method. This can greatly improve printing efficiency. Company system: collect relevant normative systems of all departments of the unit, such as: administrative management system, employee handbook, financial management system, reimbursement management system, etc. When it comes to consumption upgrades, everyone will think of labels such as aesthetics, personalization, and quality. The transformation of consumer demand accompanied by economic development in recent years has made enterprises need to produce more personalized products, which requires the integration of enterprise resource management systems. Flexible support. The key is that the enterprise integrated resource management management platform is close to the needs. Enterprise-level Internet services are booming, and traditional software vendors and emerging Internet companies have launched applications based on different scenarios. Multi-platform access (seamless connection with mainstream platforms can support automatic order synchronization, automatic inventory synchronization, new product release, product off-shelf, automatic upload of product information such as unit price, description, name, postage template, etc.)Material data and customer data are entered by multiple departments and users at the same time, which leads to the incoordination of data information, and also destroys the premise of data consistency required by the system, re-plans and determines the enterprise process and system process, so that the system data information is truly connected , to provide reliable data basis for future development planning, thereby ensuring the unification and smooth flow of data, and laying a solid foundation for enterprise informatization.

If you still don’t understand the above content, you may wish to consult LongRiverTech Software, which focuses on the customized development of enterprise digital software, providing customized software development from erp system, invoicing software, mes system, order management system, project management system, etc. And provide long-term landing, update and upgrade services.