The development prospect of mobile building ERP supply chain site

Building ERP supply chain site is a collection of current management technologies and management concepts. It is a software for enterprises to manage their employees' daily work and monitor their work effects. After all, the 21st century is the age of network economy and e-commerce information, and traditional management obviously cannot meet the needs of actual development. The complete product design change resource management system not only provides common functions such as day-selection, single-batch, whole-batch, and immediate changes, but also provides the function of running out of changes: the system is based on the user's settings , can automatically use old materials first, and switch to new materials automatically after the old materials are used up; and provide corresponding reports to show the estimated future inventory status after material changes, which is convenient for management. The small trader resource management procurement function needs to focus on procurement-related functions. For example: BOM distribution, one-click inquiry, supplier management. The configured and updated tens of millions of price libraries support the realization of BOM instant report. What are the functions and advantages of building ERP supply chain site?

For most building enterprises, building ERP supply chain site focuses on the unified management of logistics, capital flow and information flow in the process of purchase, sales and production. Usually, design, type, engineering, etc. Enterprises, as a node in the industrial chain, only pay attention to the material and capital transactions of upstream and downstream suppliers and customers directly related to themselves, as well as their own production, processing and assembly flow.

LongRiverTech building ERP supply chain site provides a full set of project consulting, product customization development, project deployment and implementation, and online cloud platform customization and operation of technical services to meet the industry needs of design, type, engineering, etc..

The LongRiverTech process flow includes: process card, QR code operation, materials and schedule, and can meet the special industry needs of the design, type, engineering, etc..

The human resources and salary management functions of the resource management system include: organizational management, human files, recruitment interviews, personnel transfers, training management, examination management, basic settings, salary item settings, salary entry, and new salary tables. The micro member management system is a business application platform based on WeChat. It is mainly composed of WeChat official account and mobile business application platform. Help enterprises realize the marketing and service center with massive WeChat users as the entrance, and implement the mobile Internet strategy. OA system performance management includes: assessment categories, assessment templates, assessment scores, assessment extraction items, my performance, performance query, assessment tasks, and task planning arrangements. Internal communication: Provide online instant text communication function, when the file arrives, it will be reminded by instant message. Unlimited expansion of file attributes according to needs. Through the business intelligence analysis system, we can keep abreast of the various capabilities of personnel and the completion of KPI indicators, and quickly evaluate and adjust personnel efficiency. Prevent financial risks, keep abreast of the company's financial situation, and make targeted adjustments to understand the company's profits and costs in real time. Keep abreast of whether the existing product structure is reasonable, the situation of unsold goods, whether the inventory turnover is within the expected range, and the implementation of KPI indicators. Real-time control of member dynamics, formulate and track member service plans, understand old customer contribution rate, return rate, etc., and carry out special follow-up for high-quality members. . Understand the existing store operating conditions, the completion of KPI indicators, and make timely and targeted adjustments. Support multiple platforms, computers, tablets, and mobile phones, and check the operation status anytime, anywhere, truly liberating managers from the office. Future development depends on design innovation and response to non-standard products, based on "order-driven, production-oriented" digital management transformation, and the common management and control difficulties in the industry mainly exist in new product quotations, machine planning, and process tracking management.

LongRiverTech building ERP supply chain site retail return order includes: create retail return order, view retail return order flow, reverse retail return order, view retail return order documents, print retail return order documents, and export retail return order documents. LongRiverTech procurement management is an important module of building ERP supply chain site, including: purchase order, purchase return order, purchase receipt, business document, sales order, intelligent replenishment, purchase plan, approval and tracking, purchase order, purchase delivery Planning, supplier inquiry, historical quotation and transaction price, supplier contract and other functions. LongRiverTech building ERP supply chain site supports the natural value-added, farming and planting of products.

The biggest feature of resource management is the integration of the entire enterprise information system, which is more functional than the traditional single system. Integrate the data that was originally dispersed in all corners of the enterprise, making the data consistent and improving its accuracy. In an integrated environment, the information generated within the enterprise can be obtained and applied anywhere in the enterprise through the system. The resource management system will make the horizontal connection between the parts effective and close, so as to improve the management performance. Through the cooperation of the resource management system, the enterprise and the raw material supplier are closely integrated. Resource management is the integrated management of the entire enterprise information, focusing on integrity. The key to resource management is "informatization of actual work", that is, to express the content and methods of work in reality with informational means. Real-time understanding of the company's operations and the implementation of its goals. Make market adjustments in time, and track and predict market dynamics. Improve personnel efficiency and reduce personnel costs. Provide efficient, accurate and timely data analysis, and provide powerful data support for enterprise decision-making. The custom process uses tools like word, visio and other tools combined with the company's process to realize process reorganization and customize the process in the software. Traditional manual management methods have been unable to control the production capacity of on-site machines, mold conditions, teams and production lines, and are facing challenges such as low utilization of production capacity resources and unable to quickly respond to customer needs. There are many types of production capacity, fast replacement, and frequent design changes, which pose a great challenge to the company's ability to accept orders. How to effectively integrate resources from research and development to production/planning and supply chain. With the general trend of consumption upgrading, the industry is increasingly focusing on user experience, how to upgrade products, marketing channels, and service methods to meet user needs. Empower digital transformation through the intelligent value of the building ERP supply chain site cloud platform, take advantage of the opportunity to upgrade informatization management, lay out informatization to open up key operational links, and create a diversified industrial kingdom. Group commodity sales final accounts: It is used to monitor the sales plan of each brand of the group by category, such as the annual plan and quarterly plan implementation of suits and trousers. What is a resource management system? What does resource management mean? Resource management is the general term for various types of software in an enterprise. In addition to functions such as production resource planning, manufacturing, finance, sales, and procurement, there are also quality management, laboratory management, business process management, product data management, inventory, distribution and transportation management, and human resources. Resource management and periodic reporting systems are both areas of resource management. It jumps out of the boundaries of traditional enterprises and optimizes the resources of enterprises from the scope of supply chain. It is a new generation of information system based on the era of network economy. It is mainly used to improve the business process of the enterprise to enhance the core competitiveness of the enterprise. Generally, industrial products go through three stages: engineering design, process manufacturing design, and manufacturing. Correspondingly, EBOM, PBOM, and DBOM with very similar names but very different contents are produced in these three processes. These are the three main BOM concepts. The e-commerce management system deploys online enterprises to realize the integration of online and offline enterprises. B2C is the abbreviation of Business-to-Customer, and its Chinese abbreviation is "Business to Customer". "Business-to-customer" is a mode of e-commerce, also known as commercial retail, which sells products and services directly to consumers. This form of e-commerce is generally dominated by online retailing, which mainly uses the Internet to carry out online sales activities. B2C means that enterprises provide consumers with a new type of shopping environment through the Internet - online stores, where consumers shop and pay online through the Internet. B2B refers to the business-to-business marketing relationship, which closely combines the enterprise intranet with customers through the B2B website, and provides customers with better services through the rapid response of the network, thereby promoting the business development of the enterprise (Business Development).

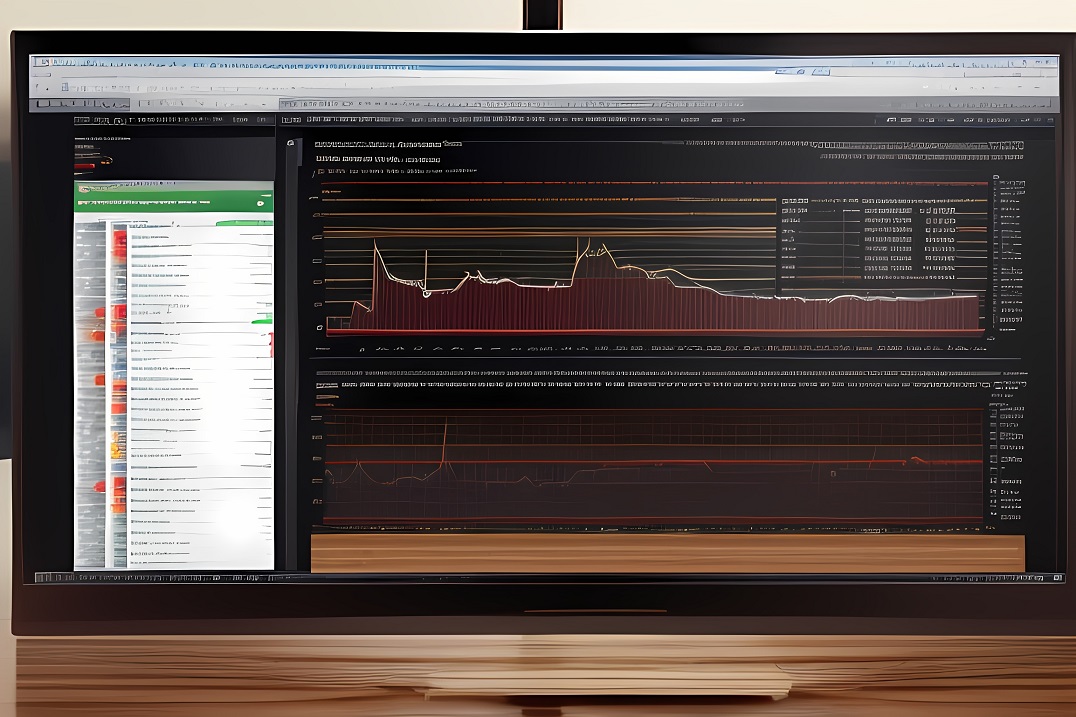

LongRiverTech building ERP supply chain site processing and manufacturing includes: BOM configuration, processing cost sheet, assembly and disassembly sheet, and product valuation adjustment sheet. Through LongRiverTech building ERP supply chain site, funds can be entered and withdrawn, and services such as receipts, payment slips, income slips, expenditure slips, and transfer slips can be executed. A practical building ERP supply chain site must be able to provide multiple perspectives from different dimensions to help customers observe the operation of data and make decisions effectively and efficiently. Through LongRiverTech building ERP supply chain site statistical report, you can view business flow, purchase management data, sales management data, inventory management data, processing and manufacturing statistical data, import and export trade and capital management data. LongRiverTech's processing and manufacturing functions include: BOM configuration, processing cost sheet, assembly and disassembly, and valuation adjustment sheet. LongRiverTech building ERP supply chain site account management includes: our account and counterparty account.

The planned BOM bill of materials (Bill Of Material for short) is a detailed record of all the lower-level materials and related attributes used in a project, that is, the affiliation relationship between the master part and all components, unit usage and other attributes. In some systems, it is called It is a material table or a recipe material table. In order to correctly calculate the quantity and time of material demand in the resource management system, there must be an accurate and complete product structure table to reflect the quantity and subordination of the produced product and its components. Among all the data, the Bill of Materials has the greatest impact, and its accuracy requirements are quite high. The production management functions of the resource management system include: cost accounting, production files, bill of materials, production planning, material demand planning, production tasks, and material picking management. OA system vehicle management includes: vehicle reservation, my application, use management, vehicle information, vehicle maintenance, vehicle accident, vehicle annual inspection, vehicle refueling, vehicle insurance, vehicle violations. Building ERP supply chain site passive service of the cloud platform is self-empowerment, with the latest digital technology, intelligently connects each user, and makes the service go ahead of the user's needs! building ERP supply chain site The cloud platform provides enterprises with intelligent integration solutions and services that are truly profitable. Formulate reasonable procurement and production plans. Building ERP supply chain site cloud platform has also added a batch demand planning subsystem to better prepare the production plan and material procurement plan for products and semi-finished products of all stages according to the order, which can be better suitable for planned production and order receiving The production mode greatly improves the efficiency and accuracy of work. It helps to improve customer satisfaction and bring greater benefits to the enterprise.

In general, building ERP supply chain site is an information system centered on management accounting, which is used to identify and plan enterprise resources, so as to obtain customer orders, complete processing and delivery, and finally get payment from customers; building ERP supply chain site will All internal resources are integrated to achieve the best combination of resources and the best benefits.